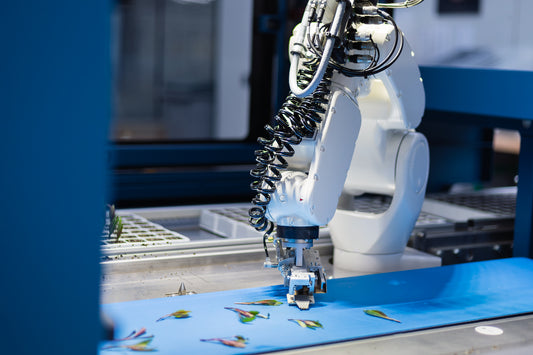

Kolekcja: Nursery Processes Robotization

Agriculture robotization enables fluid, precise mass production with reduced human input to achieve timely delivery of food, ornamental and forestry plant material and increase bottom line by:

- Improving operational efficiency to maximize output.

- Removing barriers to productivity.

- Implementing strategic alignment.

- Eliminating unnecessary costs.

- Maximizing use of space.

- Identifying under utilized human resources.

- Investing in employee experience.

- Improving customer experience.

These plant production automation machines are made to adapt to agronomy, horticulture, scientific research laboratory, breeding, propagation nurseries and forestry needs. Each machine is designed to handle one or a range of landscaping, aquatic, bulbs, cut flowers, carbon management, reforestation, afforestation and edible crops.

Automated processes include but are not limited to industrial plant propagation, pot destacking and filling, plug transplant, bulb handling, rooted and unrooted plant material planting and up potting in soil and growing media, young plant clipping, cutting selection and sticking, grafting, grading and sorting, germination correction, DNA sample collection and plantlet watering.